A Guide on the Different Types of Motor Mounts

Motor mounts might not be the first thing that comes to mind when considering your vehicle’s performance. However, these crucial components stabilize the engine, reduce vibrations, and enhance your driving experience. Whether you’re seeking a smoother ride or greater durability, choosing the right motor mount is essential. Here’s everything you need to know.

What Are Motor Mounts?

Motor mounts are the unsung heroes of your vehicle’s suspension system. These components secure the engine to the chassis, absorbing vibrations and ensuring smooth operation. By doing so, they protect both the engine and the car’s structure from wear and tear.

Each motor mount is a combination of materials like rubber, metal, and bolts, working together to minimize vibrations. Without them, engine vibrations would disrupt your drive and potentially damage other parts of the car.

Common Types of Motor Mounts

Choosing the right motor mount depends on your vehicle’s needs. Let’s explore the most common types:

- Rubber Motor Mounts: These are cost-effective and provide excellent vibration dampening, making them ideal for standard vehicles. However, they may crack under heavy stress over time.

- Hydraulic Motor Mounts: Filled with fluid, these mounts deliver superior vibration control. They’re commonly used in luxury vehicles but come with a higher price tag and potential leak risks.

- Metal Motor Mounts: Offering maximum strength, these mounts are best for high-performance vehicles. However, they transmit more noise and vibrations.

- Polyurethane Motor Mounts: A middle ground between rubber and metal, these mounts are durable but may transmit more vibrations compared to rubber.

- Active Motor Mounts: These high-tech mounts use sensors to adapt damping based on driving conditions, ensuring optimal performance.

Which Material Is Best for Your Needs?

The material of a motor mount plays a key role in its performance and durability:

- Rubber: Ideal for comfort and noise reduction but susceptible to cracking over time.

- Polyurethane: More durable and resistant to wear but less heat-resistant.

- Metal: Excellent for performance but harsh on noise and vibration.

- Hydraulic: Great for reducing vibrations, though they may suffer from fluid leaks.

Your choice depends on your vehicle type, driving conditions, and desired performance.

Signs of Failing Motor Mounts

Motor mounts endure significant stress over time. When they fail, the symptoms are hard to miss:

- Excessive Vibrations: You may feel these through the steering wheel or seat.

- Clunking Noises: These often occur during acceleration or when shifting gears.

- Engine Movement: Visible shifting of the engine under the hood indicates worn mounts.

- Cracks or Leaks: Hydraulic mounts may leak fluid, while rubber mounts may show visible damage.

Ignoring these signs can lead to further damage, making timely replacement critical.

Hydraulic vs. Solid Rubber Mounts

Deciding between hydraulic and solid rubber mounts depends on your priorities:

- Hydraulic Mounts: These excel in vibration control and comfort, making them ideal for luxury vehicles. However, they are more expensive and prone to leaks.

- Solid Rubber Mounts: These are durable and cost-effective, often preferred for budget-conscious drivers. Yet, they might not offer the same level of noise reduction.

For heavy-duty or performance-oriented applications, a balance of durability and functionality is key.

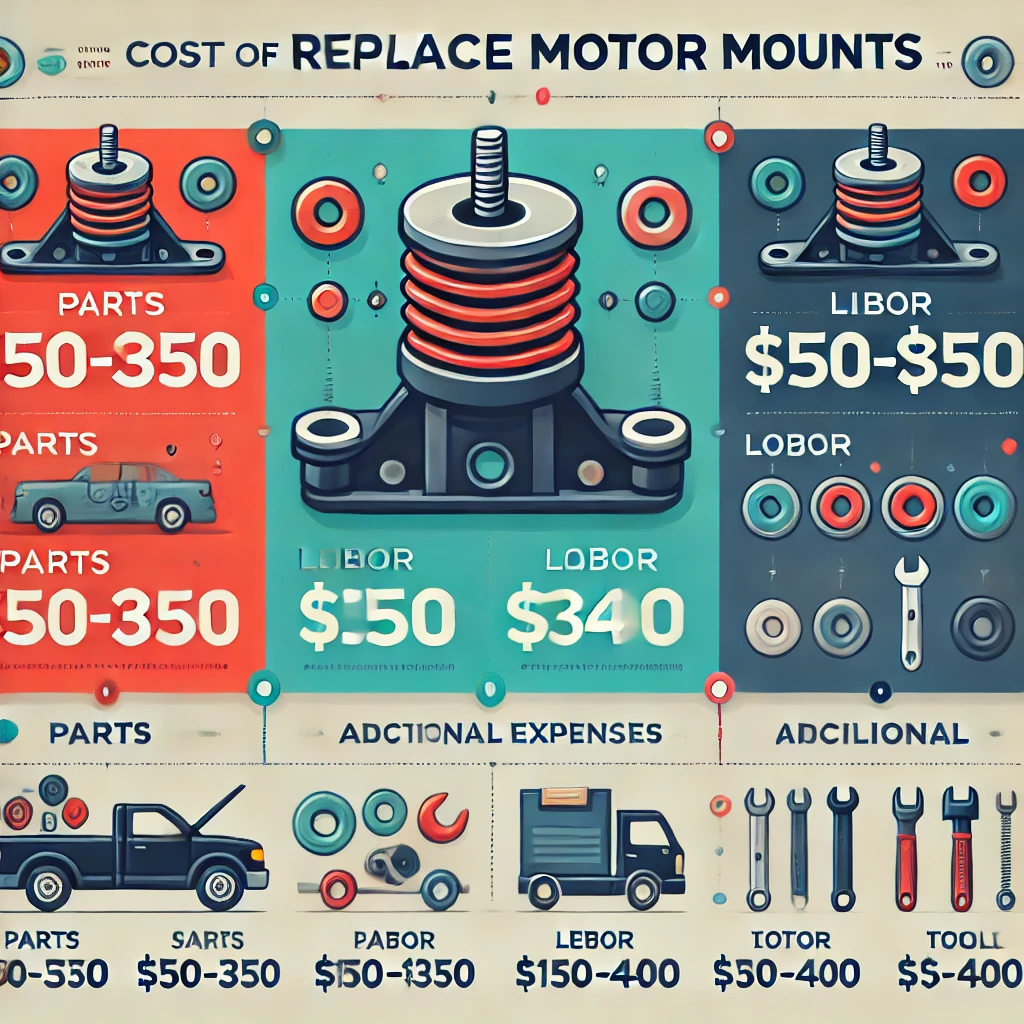

Cost of Motor Mount Replacement

Replacing a motor mount involves both parts and labor costs. Here’s a breakdown:

- Parts: Rubber mounts range from $50 to $100, while hydraulic mounts can cost $150 to $350. Active mounts are even pricier, starting at $300.

- Labor: Depending on the complexity of your vehicle, labor costs can range from $150 to $400.

On average, expect to pay between $300 and $750 for a complete replacement.

Customization for Specialized Applications

Not all vehicles are the same, and neither are their motor mounts. Custom designs cater to unique requirements such as:

- High-Performance Racing: Lightweight and rigid mounts for minimal movement.

- Industrial Machinery: Heavy-duty mounts designed to handle extreme loads.

- Marine Applications: Corrosion-resistant mounts for durability in wet environments.

Customization ensures your mounts meet specific needs, whether it’s enhanced durability or precision performance.

Maintenance Tips for Longevity

Proper care can extend the life of your motor mounts:

- Regular Inspections: Check for cracks, leaks, or excessive movement.

- Cleanliness Matters: Remove debris and contaminants from mounts.

- Timely Replacement: Replace worn mounts before they lead to more extensive damage.

Consistent maintenance not only prolongs motor mount life but also protects other vehicle components.

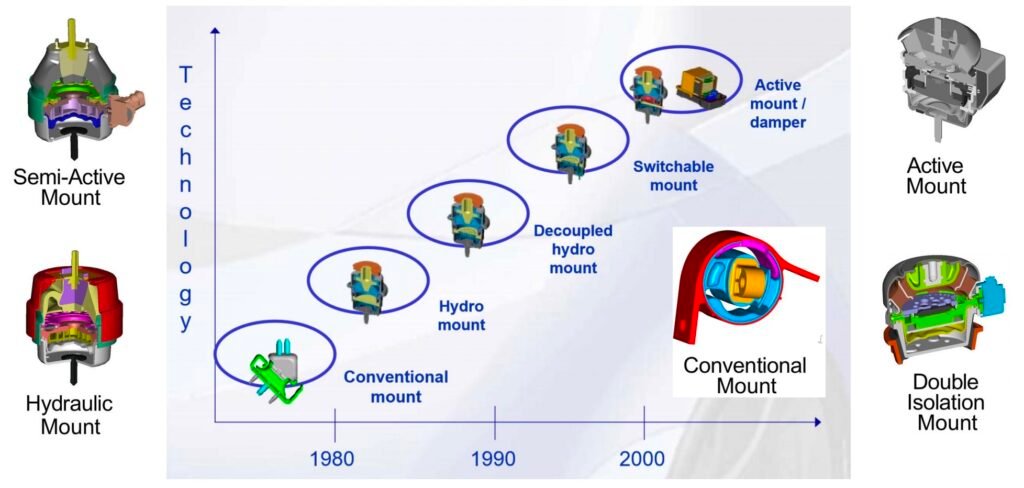

Motor Mount Innovations

As technology advances, motor mounts are becoming smarter and more efficient:

- Active Motor Mounts: Use sensors to dynamically adjust to engine vibrations.

- Magnetic Mounts: Leverage magnetic fields for precise vibration control.

- Lightweight Designs: Improve fuel efficiency while maintaining performance.

These innovations promise smoother rides and longer-lasting components, especially for modern vehicles.

Conclusion

Motor mounts may be small, but their role in stabilizing your engine and reducing vibrations is monumental. From rubber and hydraulic to active and custom designs, the right motor mount can transform your driving experience. Whether you prioritize comfort, performance, or durability, understanding the types of motor mounts available will help you make the best choice for your vehicle.

For high-quality motor mounts tailored to your needs, visit Vib-eXpert. Explore our wide range of premium products and find the perfect solution for your vehicle today.

One Response

Very shortly thuis website will be famous amid all blogging and site-building users, due to

it’s pleasant articles http://boyarka-inform.com/